Naar een nieuw tijdperk in de chirurgie

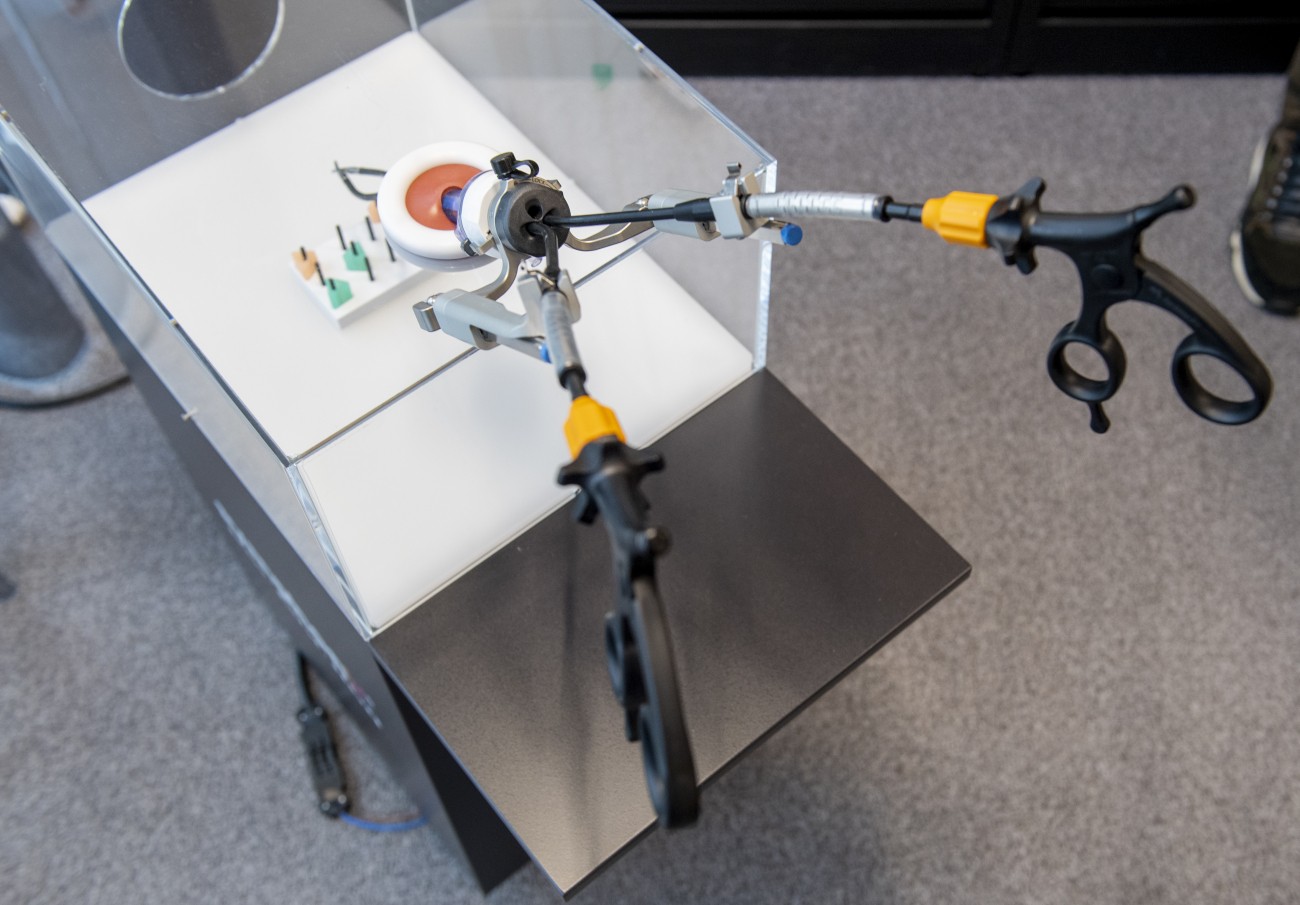

It is only over the past four decades that a new surgical technique has been widely adopted. So-called laparoscopic or minimal-invasive procedures have become the new gold standard. Surgeons now operate on the patient from the outside, with relatively short instruments - essentially cable systems with a number of optical and mechanical functionalities - that are inserted through a few small incisions. The clinical benefits from this technique are tremendous: patients experience less pain and fewer complications, and recovery times have become much shorter.

Today we're on the eve of the third period and "the holy grail" in surgery is within sight: endoluminal or non-invasive surgery. Rather than accessing patients through small incisions, surgeons use one of the body's natural openings to reach the spot where they need to operate. These procedures offer further potential improvement in clinical outcomes for patients, as well as financial and economic advantages for healthcare providers and insurers, employers and society at large. To make non-invasive surgery feasible though, a number of technological breakthroughs are required. Recently, Fortimedix Surgical achieved such a breakthrough.

What can Fortimedix Surgical do that no other company can?

"We build instruments with a number of properties that together, from a physics point of view, form a seemingly impossible combination. You can imagine that for non-invasive procedures, for example in the gastrointestinal tract, you need steerable instruments that are both long and very thin. Typically, such instruments are one or two meters in length, and ours have an outer diameter of no more than three millimeters. At the same time, they need to be flexible, robust, responsive and accurate. In terms of functionalities, you would need to assemble hundreds of individual components to build an instrument with the required capabilities and properties. In fact, some of the largest medical instruments companies in the world have spent decades and large sums of R&D money to achieve this, but none of them succeeded. The bottom-line is: we did, on the strength of our proprietary laser cutting technology. Instead of conventional laparoscopic instruments that use wires, we start from a set of metal tubes alone and use laser cutting to create the thin strips that turn these stacked tubes into an exceptionally complex and capable instrument."

What are examples of procedures where non-invasive surgery with your instruments would offer clear benefits?

"There are many, but one would be a procedure for cancer of the esophagus. In many cases this is a complicated procedure as the location is difficult to reach. The common procedure therefore is very impactful: it requires entry into the patient from two or three points, causing a lot of trauma. With our instrument none of this is needed. We enter via the mouth and throat to get to the right spot where we can perform all the necessary actions. The use of our surgical instrument would therefore result in much reduced risks of complications and much shorter recovery times.

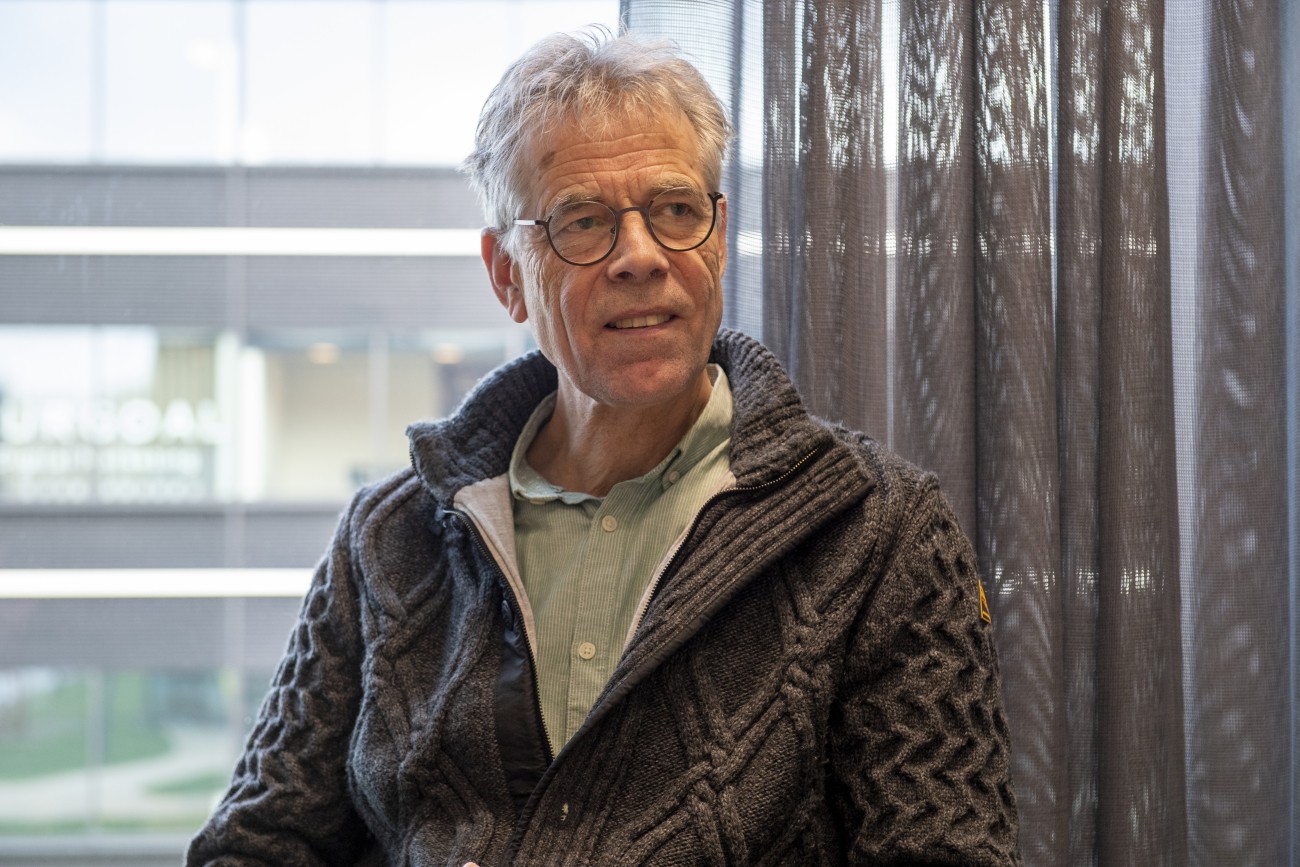

The story of how Fortimedix Surgical got to this point goes back to 2009 when Wout Bijker joined Fortimedix as CEO and part owner. At the time Fortimedix was the world market leader in stents, the thin tubes that are inserted into arteries and other types of ducts in the human body to keep them open. As a subcontracting manufacturer, a core strength was its production technology. The Fortimedix founders, fulfilling roles as company leaders and as its technological brains at the same time, had some "basic ideas" about how to apply their laser cutting technology to the manufacturing of medical instruments.

What made you decide to join Fortimedix?

"On a personal level, there was a very good match in terms of ambition and the skills and experience that I could contribute. I had always wanted the chance to run my own company, and from a business perspective Fortimedix was at an interesting stage at that time. They had a strong position in their market, a strong technology base and promising, ambitious ideas to branch out into new markets. A lack of time and resources however prevented them from developing those ideas further. When I joined, it set the two other owners free to focus much more on the development of their basic idea. To this day they have kept working on that."

It requires quite some confidence to invest in what at the time was no more than a basic idea. What made you think it could be turned into a viable business?

"First, from the conversations we had with a number of surgeons that are key opinion leaders in this field, we became convinced that with our technology we could address a relevant market need. The instruments we envisioned are an essential element of non-invasive surgery, the holy grail in surgery. Second, the ability to create a strong IP position was a critical condition for me. From day 1 I wanted to be reasonably certain that from an IP perspective we could carve out a position for ourselves. So before we decided to invest further in this idea we commissioned NLO to investigate if we would not infringe on existing patents, and if we would be able to protect our own innovations."

As Hans Hutter, Fortimedix' long-time patent attorney at NLO, explains: "You have to accept that those risks can never be reduced to zero. We were able to assure the Fortimedix team that the remaining risk were manageable, and that from an IP standpoint they could go ahead with their plans."

What were the initial years of your new company like?

"We started to devote the necessary resources to the development of our basic idea and were quickly confirmed that with our laser cutting technology we indeed had something unique in our hands. Something that allows us to create instruments that truly differentiated us from other suppliers and that, equally important, satisfy a real market need. After only three years we reached the first-in-man milestone, where an actual laparoscopic procedure was done with an instrument we built. That's an important milestone in the medical device world that proves you no longer have not just an idea, but a prototype that actually works."

But then it's only 2013. What has happened since then?

"You still have a long way to go to get from a prototype to a product that you can actually sell in the market. A 'first-in-man' procedure not only tells you your idea works, you also discover a whole list of things that need and can be improved. We went to work on those and in 2016 we received the necessary regulatory approvals. According to the norms in our industry that is quite fast, but even after 13 years in this business I can't get used to the slow pace of innovation. Before I joined this company I worked for Philips Semiconductors [currently NXP, ed.] where we sold chips with a product life cycle of one or two years. The time needed to bring an innovative medical device to the market would be an eternity in the semiconductor industry."

Why did you make this decision?

"We didn't want to be in the business of marketing laparoscopic instruments. For one, we simply don't have the scale and the resources to support the sales force you need for this. In our industry only the big corporates that employ hundreds or thousands of clinical sales reps are able to do this. Second, the unique features we can create with our technology are really needed for endoluminal instruments. We decided we wanted to bring our technology further to the point where it can be used in non-invasive surgery. And it's been a true innovation race since then. To illustrate the effort we put into this: of our total R&D spent, tens of percent go to our IP portfolio. Every two weeks, Hans spends a full day with us and together we go over all IP-related things, from monitoring filings from competitors to deciding the best timing for filing new patents ourselves. As a result, our portfolio has grown from a single patent back in 2010 and now consists of eighteen patent families that cover the solutions to all the challenges we encountered along the way. You stumble from one technological issue into the next, and you discover a hundred ways that don't work. But you learn from every failure and gradually you start seeing the light. Not so long ago we got it, and we found the way to fix a key issue."

There is still the matter of marketing and selling your instruments. How do you plan to do that?

"For that we are working with a number of companies that develop surgical robots. They are our development partners and will eventually be our customers. We are mutually dependent on each other. On the one hand, their robots don't function without our instruments. On the other, it's impossible for surgeons that use our surgical instruments to operate them manually. They will need to be supported by a robot or, more accurately, a digitized interface between the controls they hold in their hands and the business end of our instrument. In recent years there have been great advances in the technology used in such robots, from image recognition to AI, and their adoption by hospitals and surgeons. Some of these robotics companies are multibillion enterprises, and they have the marketing and sales power to bring about the shift to non-invasive surgery.

When do you expect this to happen?

"Given the pace of innovation I talked about, that could well take a couple years."

Your original patents will almost expire then. Is that a threat?

"Not really. We have made so much progress since we filed our first patent, even if competitors would copy what we described in that, we would still be ten years ahead. Next to that we have built a substantial portfolio of trade secrets relating to our manufacturing technology. We feel confident competitors cannot make instruments with the same capabilities, properties, and cost as ours without infringing on our IP rights. So we believe a company with the ambition to market non-invasive surgery robots has no other option than to work with Fortimedix Surgical. That is the position we created for ourselves by investing so much for so long in R&D and in the IP-rights that protect our innovations."