How TenCate Grass develops sport fields that do not require an annual 6 million liters of water

- this article is only available in English -

Colin Young thinks he has the best job in the world for him. His whole professional life has revolved around synthetic grass or turf, starting with a PhD at Loughborough University (UK) on the design and construction of water-based hockey fields, and continuing until his current position as global director of R&D at TenCate Grass, by far the biggest company in the industry.

Since he took this job about five years ago, annual turnover has quadrupled to well over 1 billion euros. Not that he personally claims any credit for this impressive growth. Part of it is the result of a string of acquisitions that has turned TenCate Grass into a vertically integrated company: it no longer mainly produces the fibers and yarns from which turf is made, it now also designs, manufactures, installs and recycles the complete systems. The company, headquartered in the town of Nijverdal but with a global presence, has also captured a growing share of growing markets, particularly in Europe and the USA. In terms of square meters of turf the landscaping market is the biggest for TenCate Grass, but it's the sports market that generates most of the revenue and drives most of the R&D.

How far has the technology come since your PhD days?

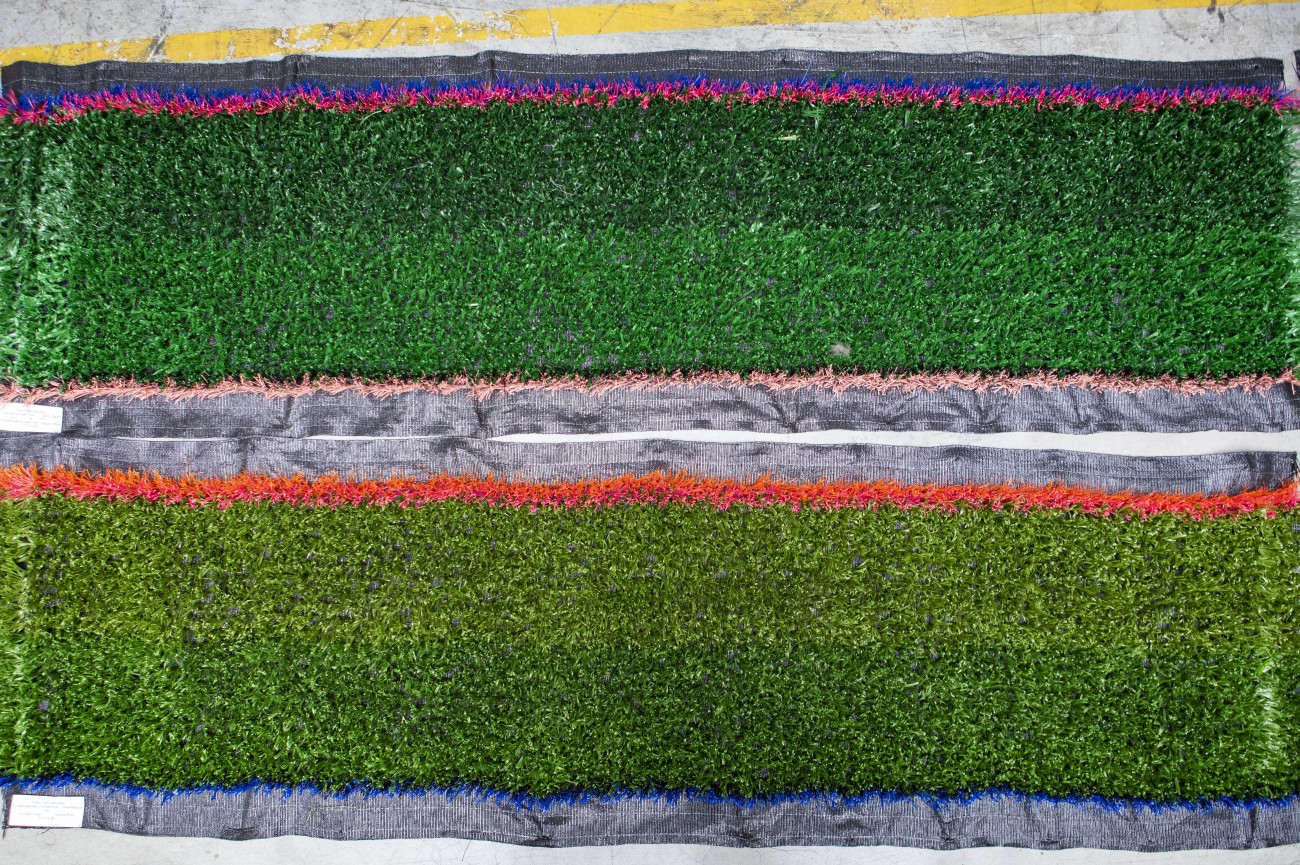

"The technology started already in the 1960s with Astroturf, named after the Houston Astros baseball team that played on this almost carpet-like structure made of very dense, short fibers. Today the most commonly used type of synthetic grass has much longer fibers, and inside the turf there is typically a stabilizing infill like heavy sand, and on top of that a performance infill, most often rubber granules made from end-of-life tires. The playability of those kind of systems got much closer to what people were used to and that has really expanded the market. These granules can easily get in the environment uncontrolled however, and in the near future the use of these so-called intentionally added microplastics will be banned in the EU and other markets. So we've been working for several years now on the next generation of turf. There are two main routes we're looking at. One is replacing rubber infill with natural infill, from trees or crop-produced waste for example, that gives a similar performance. The second option are non-filled systems where we do some clever things to the yarns that allow them to provide the same functionality and benefits that the infill is doing."

If you say the playability of synthetic turf has been much improved over the years, how relevant is the criticism from professional football players that say they don't like to play on it?

"It is still relevant, and we have ongoing discussions and research activities with professional players. It's true that if you have good quality grass, and a lot of resources and money to maintain it, and you don't use it very often, you can have absolutely fantastic grass playing fields. But that is only reserved for the privileged few that play in those high-end stadiums. Our market is not primarily the top of the pyramid. Most clubs and certainly municipalities don't have the luxury to spend 100,000's a year to maintain a grass field in top condition. Neither do they have the space. One synthetic turf field can be used for 60 hours or more a week, whereas if you use a grass field for more than 5 to 10 hours a week it will start to fall to pieces very quickly. So there is a resources and a convenience argument for our product: synthetic turf can carry the same amount of users as 10 grass fields, and the children and amateurs who mostly play on them don't have the same concerns as the professionals."

Still you involve professional players in your research and innovation. What do you want to learn from them?

"Indeed we have partnerships with professional clubs all over the world, not only in football but also in other sports like field hockey, rugby, American football and baseball that are far more accepting of synthetic turf than football is. Part of our R&D takes place in our Centre for Turf Innovation that offers the best facilities for testing a product in a controlled environment. We can have players come in, put sensors on them and do 3D rendering of them running in order to understand impact from the surface on them from a biomechanical point of view. But we're also keen to get a better understanding of how a product behaves in the open environment. That's why we've for instance created a field lab at the training facilities of PSV Eindhoven where we can put out prototype products. We can observe what the effects of the leaves and the sunlight and the rain are on the different materials, and we validate what the players are telling us about how it feels to them. This is all part of our efforts to emulate the grass fields used at the elite level with our fibers. The feedback we get from professional players tells us we're getting incredibly close. And if it works well for professional players, we have a very good base from which to launch the product to the wider market."

What does that breakthrough involve?

"It mainly has to do with how we tuft the product. Usually you tuft through the backing and then you cut the fibers that come up, so you get a U-shape of a fiber. We decided to not cut the fiber but produce the carpet with continual loops of fiber, which in itself is not a novel idea. But the combination of how we loop the fibers together, of how we've reengineered the fibers results in a much lower friction between the ball and the surface. Obviously we have to retain the friction for the player when they're running and turning, if the surface is too slippery they'll fall over. These are contradictory criteria but we think we've got the sweet spot with our latest product that we call Pure EP, for Extra Pace. We've recently installed a full-sized field with the support of the KNHB, the Dutch hockey federation, and there is huge amount of interest in it. It doesn't need any water at all, and even when it's dry it's just as fast as water-based fields."

You've mentioned sustainability aspects a few times, what role does that play in the world of synthetic turf?

"Next to performance sustainability is the second major driver of our R&D efforts. We're very aware that we're putting plastic in the environment. So whenever we come up with a new product, we want to make sure that we're minimizing the impact on the environment. Our products must be sustainably sourced and made, they're designed with maximum longevity and minimal maintenance in mind, and we must be able to recycle it at end-of-life. We're very much an evidence-based organization in this respect and we want to do the right thing. The search for bio-based infill materials as alternatives to rubber granules is an example. When you start to dig a little deeper they seem to be not so sustainable, because the way they are sourced adversely affects food security. If you take that into account, at the moment bio-based infills appear not to be a viable option on the scale we need it to be."

Then how has R&D improved the sustainability of your products?

"The example here is the subject of another patent that we recently filed. At the moment most synthetic turf is made from polyethylene yarns, a polypropylene backing and latex to glue it all together. These systems are expensive and time consuming to recycle because you have to physically separate the different materials first. We've come up with turf made of a 100% polyethylene. That involved the development of a new backing and new manufacturing processes for assembly of the turf. At end-of-life you just clean it, chop it and make polyethylene out of it that can be reused to make new turf. That's a much more circular solution. Fields based on this technology will be a 30,000 euro asset to the club at the end of life, whereas the older turf systems will be 30,000 euro liability to get rid of."

In general, how does IP support your business?

"The discussion we're always having is do we disclose what we're doing and go for the patent, or do we try to keep it a secret under a recipe. Our technology and the processes we use are not too difficult to reverse-engineer, and they tend to be out in the open market, and be available for anyone to cut out a sample. So we tend to go down the protection route rather than the secrecy route, and that makes patents incredibly important to us to protect our IP."

Do competitors actually cut out a piece of your turf and try to reverse-engineer what you did?

"That happens sometimes we think, so the need for protection is pretty strong. We have had a few instances though where a competitor wanted to make something we had protected. But then rather than stopping them we've sat around the table with them to see if we could get a royalty fee or an agreement for them to use our IP in certain regions. So far we've tended to take a relatively pragmatic approach and that's proven quite useful for us to do. That said, we are confronted with some situations that I can't talk about too much that may cause us to defend some of our patents a bit more aggressively in the coming years."

What role does NLO play in all of this?

"None of us in the organization are IP specialists. We have a group of people that are in charge of patents for the organization, led by myself, but it's something we dip in and out of. The continuity there is really NLO. We rely heavily on their advisory role as well as on their ability to draft patents in a technically sound and comprehensive way and also flagging what competitors are doing in terms of their patents. So NLO does a full turnkey service for us. And if we decide that we'd like to challenge what we believe is a competitor infringing on our IP, Paul and his team will be our first call to discuss what our options are."